La revue scientifique trimestrielle

Leveraging CHO cell potential in R&D and cGMP

CHO cell lines have been used extensively in the biopharmaceutical industry to generate qualitative recombinant products. Isolated from Chinese Hamster Ovaries, CHO cells show flexibility to integrate various transgenes, and scalability, through the original cell line or the CHO-K1 subclone.

However, to be used in clinical and commercial contexts, CHO cells need to demonstrate stability over the course of biomanufacturing. They thus require both R&D expertise on handling and cloning, and cGMP experience to generate and characterize CHO cell banks, which will be able to yield reproducible and safe batches of proteins.

With 25 years of experience handling hundreds of cell lines, Clean Cells is your reliable partner on both adherent and suspension models with cloning and manufacturing technologies for CHO cell lines. Our extensive portfolio of QC assays also ensures the best level of characterization for the most potent and safe CHO cells, with complementary and novel methods for monoclonal antibody characterization (ADCC).

.

Isolating your most potent clones: cell cloning using the VIPS® PRO

From polyclonal populations, the step can be important to generating a single, potent CHO cell clone which can retain the transgene of interest while showing the most promising cultivation characteristics.

The newly implemented VIPS® PRO brings automation to our evaluation expertise, allowing for enhanced cloning capabilities while bringing true proof of clonality. Combined to our QC, genetic characterization and potency expertise, our team can develop customized solution for the evaluation of the few selected clones of interest.

Transfer into cGMP context is thus made easier with a well characterized, stable and safe CHO cell seed.

Optimized cGMP cell banking with new clean rooms and technologies

Since the completion of our brand-new facility, both non-cGMP and cGMP manufacturing capabilities have been extended, with 8 GMP units in grade C dedicated to cell banking.

BSL-2 and BSL-3 laboratories combined with GMO authorizations give us the flexibility to handle various CHO cell material.

The following technologies have been implemented for optimized CHO cell banking:

- Static culture in flasks, multilayers

- Shaking culture conditions in spinner flasks, wave system, Erlen flasks

Characterization and mAB potency evaluation

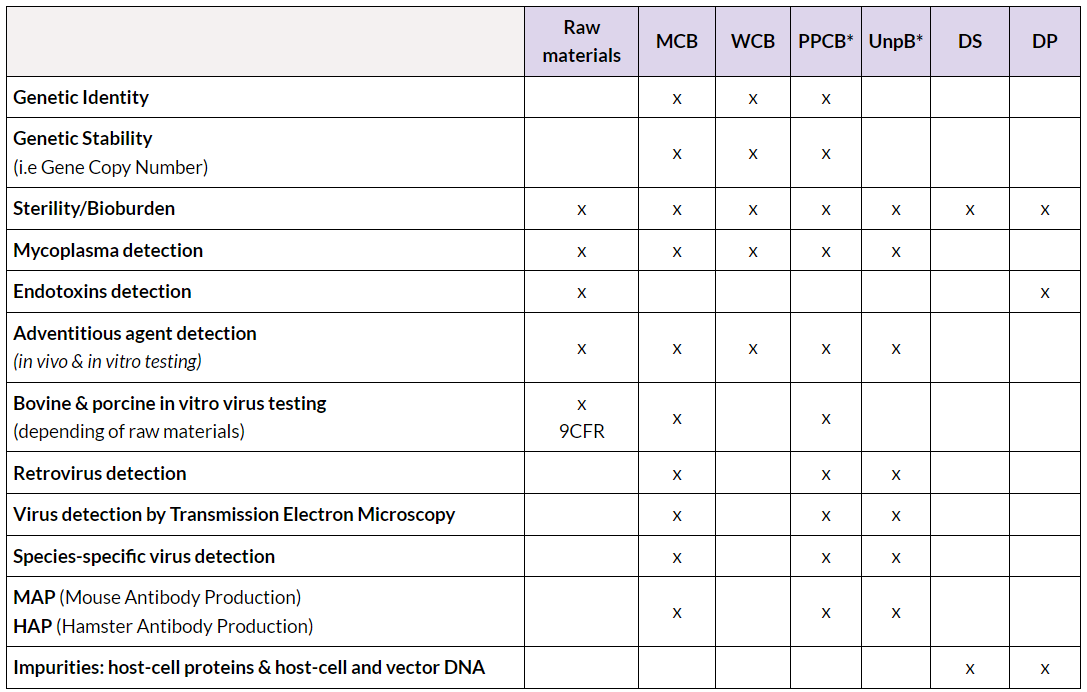

Founded on its biosafety expertise, Clean Cells has developed an impressive portfolio of non-GMP and GMP QC tests for the testing and characterization of CHO cell material or derived products.

When working with CHO cell substrates, the following tests are expected to ensure identity, safety and purity of material:

*PPCB (Post Production Cell Banks)

*UnpB (Unprocessed Bulk lots)

_

In addition, Clean Cells has specifically developed tools for the early screening or release testing of mAbs produced from CHO cell lines. In particular, our novel ADCC methods (standardized effector cells and luminescence read-out) have shown greater performances than traditional techniques while vastly improving workability.

Storage

Our LN2 storage area consists of separate room with dedicated access and 24/7 surveillance and back-up. CHO cell seeds can enter dewars after characterization for secure and long-term storage in cGMP or non-GMP environment.

Feel free to reach out to our team for an evaluation of your CHO-related project and specifications.