News & Events

Clean Mails – June 2024

Clean Biologics' News:

CHO cell, Oncolytic Virus, Mass Spectrometry...

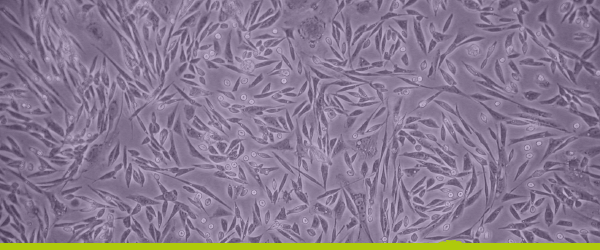

Leveraging CHO cell potential in R&D and cGMP

With 25 years of experience handling hundreds of cell lines, Clean Cells is your reliable partner on both adherent and suspension models with cloning and manufacturing technologies for CHO cell lines. Our extensive portfolio of QC assays also ensures the best level of characterization for the most potent and safe CHO cells, with complementary and novel methods for monoclonal antibody characterization (ADCC).

Naobios, your reliable partner for oncolytic virus manufacturing

Like other Advanced Therapeutic Medicinal Products (ATMP), oncolytic virus manufacturing poses a series of challenges in order to produce safe and robust viral therapies.

Oncolytic virus manufacturing must thus include preliminary development steps such as direct evolution or gene editing methods to generate cancer-specific viruses with adequate lytic properties.

While general biopharmaceutical rationales for virus-based therapies are applicable to oncolytic virus manufacturing and QC testing, some considerations need to be addressed due to their innate attributes or mode of administration. In particular, GMO status can have a big impact on overall regulatory expectations. Oncolytic virus production also requires specific processing to reach the expected concentrations for such products and/or overcome obstacles generated by the size of viruses.

Naobios gathers 20 years of expertise spanning the whole range of virus- and vector-based therapies. Within state-of-the-art cGMP facilities, Naobios supports companies with diverse oncolytic virus manufacturing needs, addressing all hurdles typically encountered by sponsors.

GMP capabilities in mass spectrometry with the Waters Xevo G3 QTof

Biologics have transformed healthcare with their remarkable therapeutic potential and specificity. To develop and market these biopharmaceuticals effectively, a deep understanding of product variability, degradation pathways, and production processes is essential, all of which made possible by methods such as mass spectrometry under GMP. Analytical labs face the challenge of optimizing instrument utilization to meet the demand for precise qualitative and quantitative data. This necessitates versatile multifunctional equipment that can adapt to diverse applications, such as GMP-ready Liquid Chromatography-Mass Spectrometry/(LC-MS) for comprehensive testing of biologics, enabling detailed characterization and quantitative analysis to ensure product quality and safety.

Increasing biologics manufacturing capacities

Biologics manufacturing encompasses all the processes which allow living material to be transformed into therapies, or biopharmaceuticals. Part of biologics production requires the generation of banks of cells and viruses which are further used to produce large molecules therapeutics. Cell and virus bank manufacturing requires both technical knowledge and strict compliance to cGMP guidelines to provide safe and potent material to biologics manufacturing.

With 23+ years of experience handling hundreds of cell and virus models, Clean Cells has positioned itself as a leader in cell and virus banking, providing complementary characterization and storage services.

Our state-of-the-art cGMP facility launched last year welcomes our biologics manufacturing capacities, providing 8 new clean rooms designed for all types of biopharma projects and equipped to meet production specifications for both adherent and suspension cells. A newly implemented cell cloning platform further integrates our capacities, from initial cloning and selection of the most potent cell lines to fully characterized, ready-to-use cGMP cell & virus banks.